There are several commonly used types of resistors: carbon, thin film, thick film, metal foil or wirewound. Each type has specific characteristics suitable for different applications with varying requirements. Thick-film resistors are made of a mixture of conductive particles (metallic grains) with a glassy binder and an organic fluid.

This “ink” is printed on a ceramic substrate and heated in an oven. During this firing process the conductive particles within the glassy matrix are fused to the substrate and form the resistor. Thin film resistors are fabricated by sputtering a metal or alloy on an isolating substrate. Wirewound or foil-resistors are made from

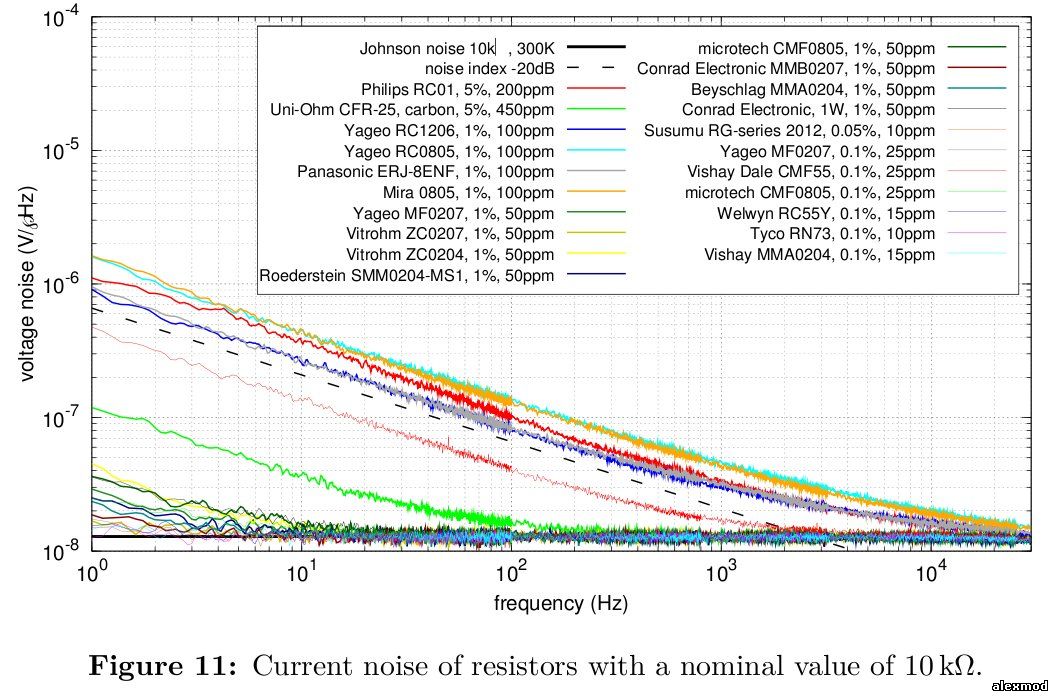

foils and wires of different metal alloys attached to an isolating substrate. All of them have in common that the total noise can be divided into thermal noise and excess noise. Excess current noise is the bunching and releasing of electrons associated with current flow, e.g. due to fluctuating conductivity based on imperfect contacts within the resistive material. The amount of current-noise depends largely on the resistor technology employed.

|